Need Help Comparing Vacuum Sealers?

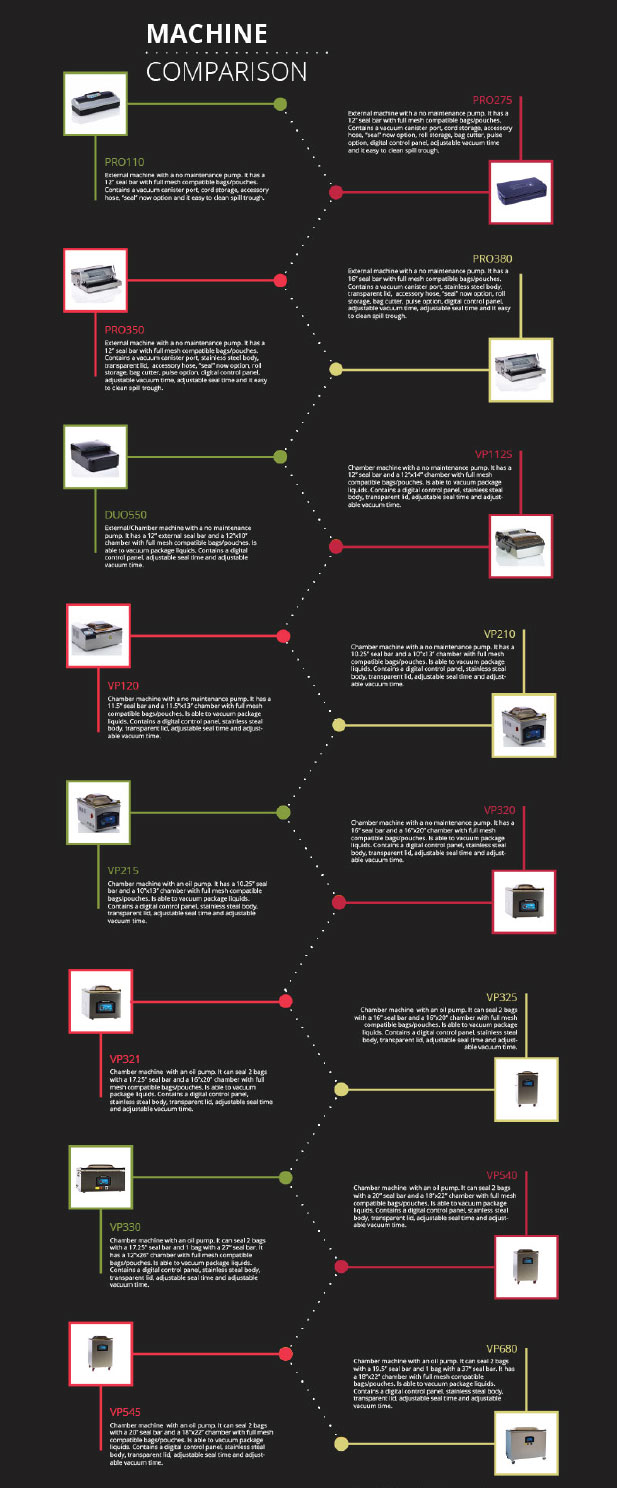

| It can get a little bit overwhelming out there when you are in the market for a vacuum sealer. If you find yourself getting a little confused as to what type of unit you really need check out our machine comparison chart. For an easy to read (and printable) chart version, download a PDF version here. We start with the basic suction sealers for light home use and work our way up to commercial sized chamber units more suited to industry. Options to keep in mind: 1. Suction When using a suction unit, you place the opening of the bag inside the opening of the unit and a literal sucking mechanism is used to pull the air out of the bag. This is ideal for many small home use cooking and storage task using dry goods. 2. Chamber Chamber sealers are ideal for sealing any moist or liquid product. The bag with the item you are sealing is placed inside the chamber of the unit, from here all of the air is evacuated from the unit, including the bag. Since no direct suction is involved liquid remains inside the bag. 3. Oil Pump A chamber vacuum sealer with an oil pump is able to be run continulously without the need for breaks that a dry pump unit will need. An oil pump is ideal if you will be sealing a large quantity of items, perfect for processing game or sealing product for a business a continuous rate. 4. Gas Flush Option The gas flush option is perfect if you need to package anything fragile, that may be damaged during the usual vacuum sealing process, think potato chips and other similar items. Gas flush inserts a gas such as nitrogen into the bag to take up space during the vacuum process, leaving your fragile items undamaged.  |

| To find more helpful information check the Help Center and the Fresh Bites Blog regularly, and fell free to reach out to us here as well. |