How To: Make Beef Jerky with Hickory Using Your Chamber Sealer

Whether it was the Native Americans who dried thin strips of Buffalo first or it was the Incas who did the same with Lamas I’m not too sure, but we do know that “Ch'arki" or what we call Jerky ‘round these parts allowed us to store protein for long periods of time without refrigeration. Not only that but it was compact, light, easily transportable and tasty to boot!

It’s theorized Jerky making began by drying the thin strips of meat on large flat stones out in the sun. Later as the technique was refined a low fire was added not to cook the meat but to create smoke to keep the flies and other insects at bay which inadvertently added a nice smoky flavor element to the meat. Eventually enclosed drying boxes and later shacks were built to refine the process even more. Nowadays there are basically two methods of Jerky making, dehydration or low temperature smoking and I have done and continue to use both methods. Today’s method is a bit of a hybrid using the dehydrator for its indoor convection convenience along with a bit of liquid smoke in the marinade for that outdoor flavor.

When preparing any raw meat regardless of the variety it can be tough to cut thin and will be far easier to slice when it’s sort of frozen. With that in mind if your meat is frozen, partially thaw it, if it’s fresh, partially freeze it! Then of course how do you cut it? The general rule of thumb when cutting meats for eating is we generally cut against the grain of the meat. This makes it easier to chew, slice and eat. With Jerky though, we have the option of slicing WITH the grain, so that it’s chewier and holds together well. Or slicing against the grain offers Jerky that is easier to chew but can crumble when sliced thin, the option is yours!

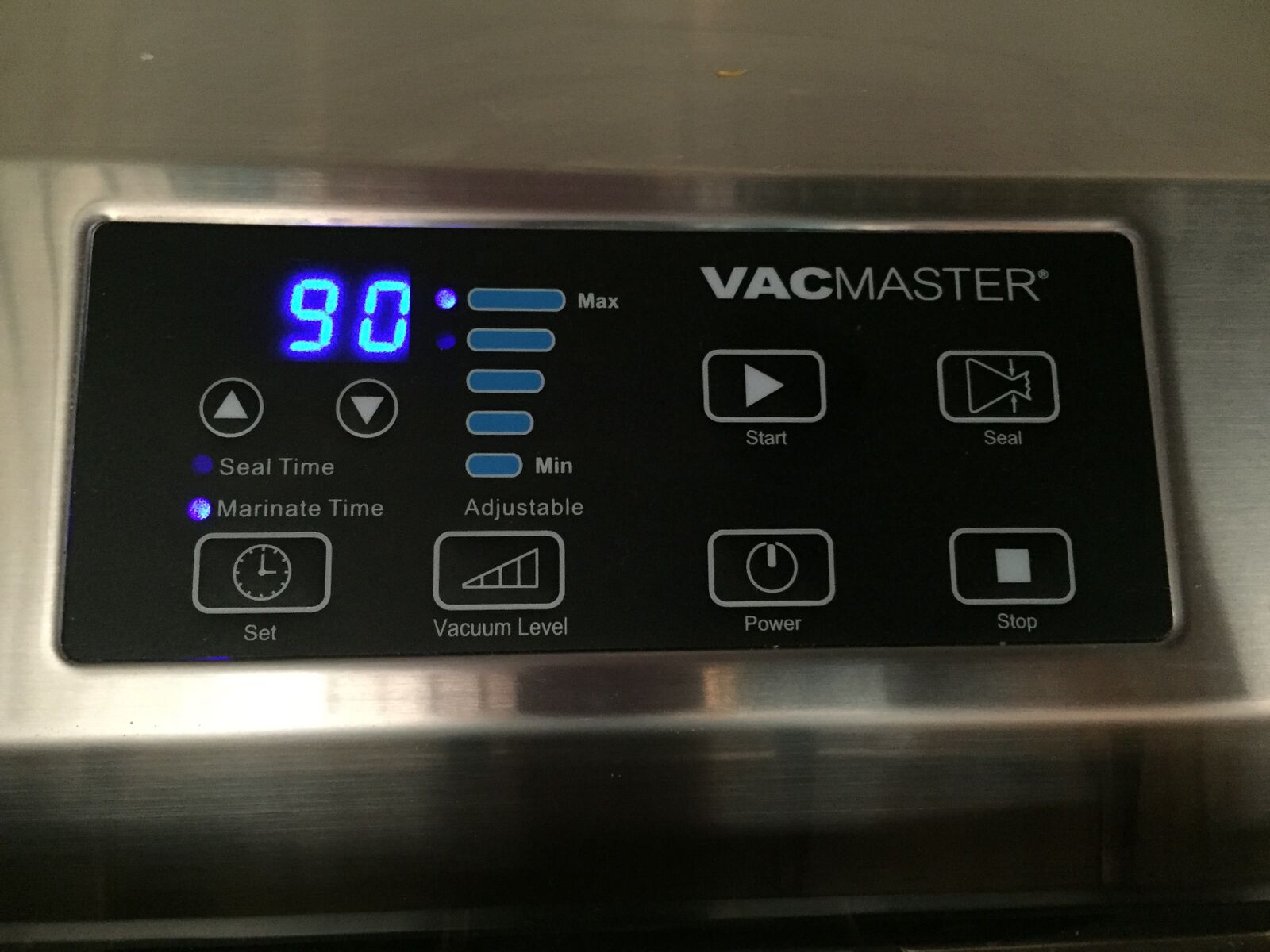

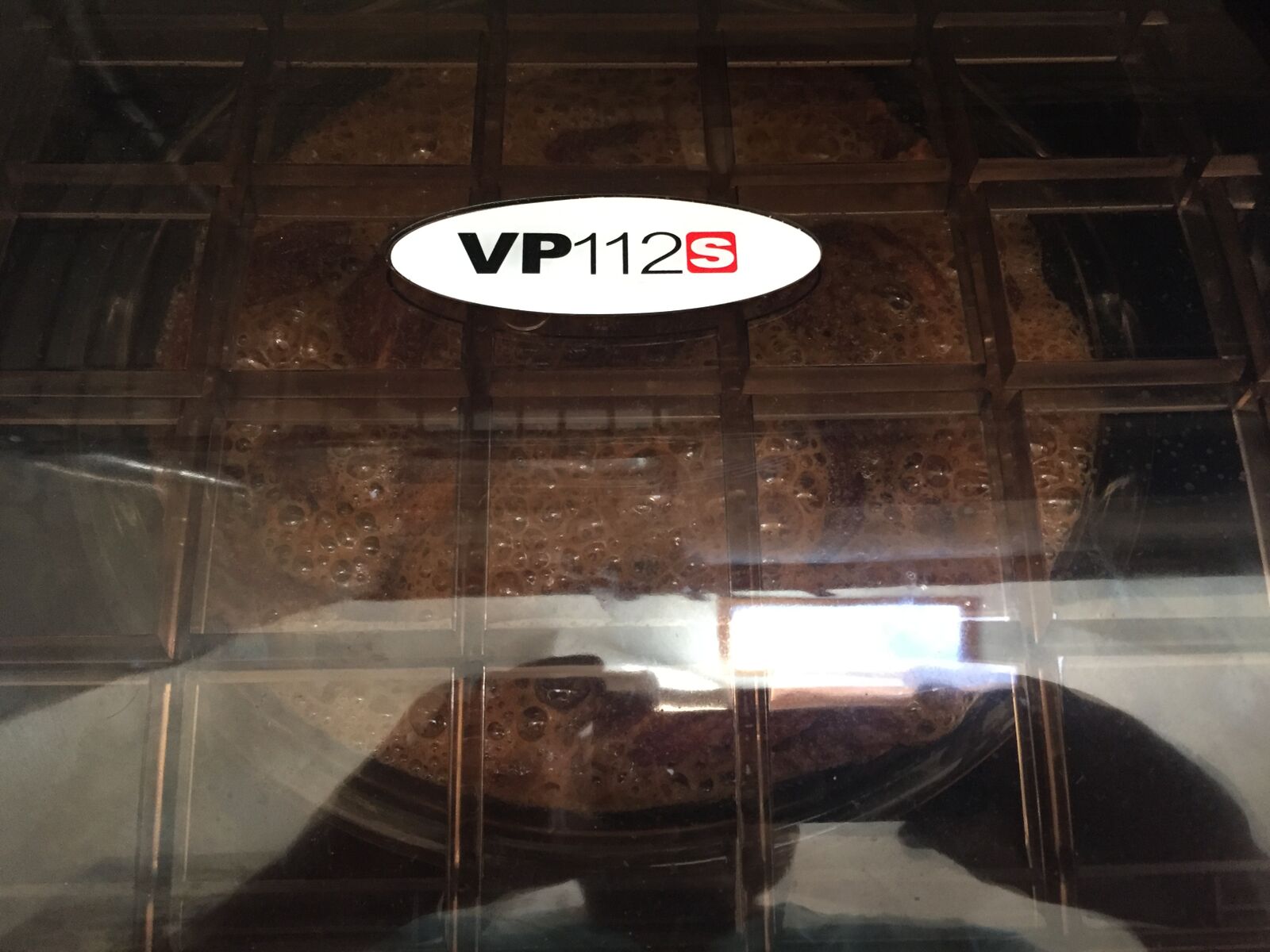

I’m not sure when marinades were added to the process but I can’t imagine not flavoring the jerky in some manner. The only issue I find with marinades is that the length of time usually adds another day to an already lengthy preparation time, VacMaster® to the rescue! Vacuum marinating can dramatically decrease the standard refrigerated submersion technique. I’m able to approximate a standard overnight marination in my refrigerator in roughly 90 minutes using the marinade function on the VP112S! That means depending when I have my morning coffee I can have perfect jerky finished and packed all in one day!

I chose readily available beef for today's recipe but you can easily replace it with Venison, Buffalo, Elk or if available grab your closest Llama!

Ingredients:

• 2 1/2 - 3 pounds flank steak, trimmed of any excess fat and sinew

• For the smoky maple marinade...

• 3/4 cup maple syrup, pure

• 1 cup soy sauce

• 1 tablespoon liquid smoke, high quality, hickory, mesquite, etc.

• 3 tablespoons Worcestershire sauce

• 2 tablespoons black pepper, freshly ground, fine

• 2 tablespoons roasted garlic powder

• 2 tablespoons onion powder

Directions:

For the meat…

1. Place the trimmed flank steak gently wrapped in plastic wrap on a plate or suitable tray (this helps keep the meat flat and in a suitable form for cutting) in the freezer for 1 to 2 hours to firm up.

2. Remove the flank steak from the freezer, unwrap and thinly slice the meat with or against the grain (it’s your choice!) into long strips and reserve.

For the marinade…

1. Place all of the marinade ingredients in a suitable bowl to hold the meat and whisk until thoroughly combined; making sure the maple syrup is fully dissolved.

2. Add the meat to the marinade and gently toss together until all the meat is fully coated.

3. Place the bowl or any other suitably sized bowl or pan into a VacMaster Chamber machine with the marinade function and set the marinade controls to 9 and press start. As each marinade cycle takes 9 minutes this procedure will take 81 minutes or 1 hour and 35 minutes. This brief marinade function will approximate 12 hours (or overnight) of standard refrigerated marination.

4. Remove slices of meat from container and layer them between paper towels to remove excess marinade.

5. Evenly distribute the strips of meat onto the racks of your dehydrator and follow your manufacturer's directions and dry the meat for 6 to 10 hours*.

6. You can place a few sheets of aluminum foil or parchment on the bottom of your machine to catch any drips to aide in your cleanup.

7. The jerky is done when it is still slightly pliable — not so dry as to be crisp and breakable - unless of course you like that kind of thing.

8. Let the jerky rest at room temperature to let the moisture left inside the meat equalize with the drier outside surface, about 1 hour.

9. Transfer the jerky to appropriately sized VacMaster® bags either plain or zipper topped and using a VacMaster® chamber or suction machine vacuum seal the bags.

10. Use the Jerky as needed!

* An additional safety step from University of Wisconsin Extension is to place the finished Jerky after dehydrating on a baking sheet, close together but not touching or overlapping. Heat in a pre-heated 275°F oven for 10 minutes to an internal temperature of 160°F – strips thicker than 1⁄4” (when raw) may require longer to reach 160°F. Remove oven-heated samples from the oven, cool to room temperature, and package. Dried jerky can be stored for 1 to 2 months at room temperature; in the freezer for up to 6 months. Vacuum package jerky to extend the shelf life of jerky.